Wood construction is becoming increasingly popular and gaining recognition, especially with the introduction of engineered wood, a revolutionary technology that is transforming how the construction industry views the use of timber. Contrary to common belief, wood is a robust, durable material that is highly suitable for both small residences and large buildings. This method is already widely used in countries across Europe and North America.

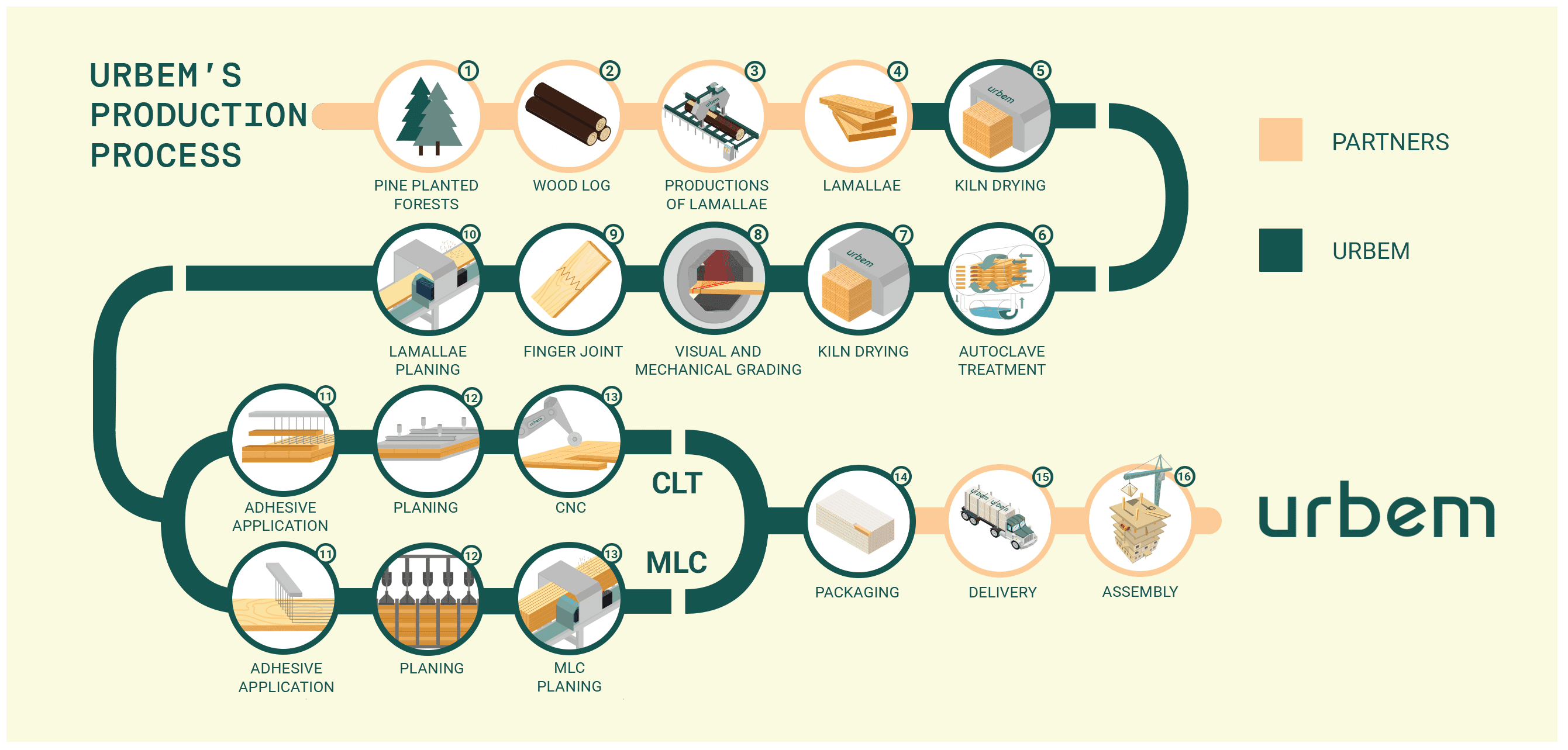

Engineered wood, internationally known as mass timber, brings the strength of forests to the construction sector. Its manufacturing process involves several stages. Here’s a brief overview of this fascinating process:

In summary:

- The wood veneers are transported to the factory, where they undergo an industrialization process.

- In the factory, the wood is dried and treated to protect it from damage, insects, fungi, and deterioration. This treatment creates a protective barrier that enhances its durability and lifespan.

- The wood is then dried again and glued in layers to form a robust structural material, ideal for construction projects.

- Finally, the produced panels and beams are machined with precise cuts, allowing for final assembly on-site, working like a giant “Lego” for construction.

However, it’s essential to go beyond understanding the process of transforming wood into mass timber when considering using this material. It’s crucial to think about the project in wood from the outset, as designing with wood in mind makes planning more efficient and streamlined. Below are some aspects to consider helping you with this purpose.

What to consider when incorporating wood, or mass timber, into your project:

- What objectives do you want to achieve by building with mass timber?

- This technology offers numerous benefits, from faster construction to reduced carbon emissions. Identifying the main goals can help determine how much mass timber will be used in the project.

-

- This technology offers numerous benefits, from faster construction to reduced carbon emissions. Identifying the main goals can help determine how much mass timber will be used in the project.

- Identify where in the project the wood will be used:

- It’s helpful to consider the strengths of the wood and where the material would perform best.

-

- It’s helpful to consider the strengths of the wood and where the material would perform best.

- Determine whether and where the wood will be exposed:

- In certain cases, if you want the wood to be more visible, it’s important to consider alternatives and methods to protect it from weathering (such as encapsulating it with a glass mass timber façade).

-

- In certain cases, if you want the wood to be more visible, it’s important to consider alternatives and methods to protect it from weathering (such as encapsulating it with a glass mass timber façade).

- What sizes are available for production?

- Each company has its own tools and available sizes that can be produced in its factory. Checking these in advance can accelerate the project and even simplify production costs. Urbem, offers a BIM library that includes the materials and sizes of pieces that can be produced for projects.

-

- Each company has its own tools and available sizes that can be produced in its factory. Checking these in advance can accelerate the project and even simplify production costs. Urbem, offers a BIM library that includes the materials and sizes of pieces that can be produced for projects.

- What machining options are available at the factory?

- Cuts, holes, and adjustments depend on the specific capabilities of each industry, as well as their own production capacity and technical limitations according to the available tools.

- These machining processes allow the material to arrive on-site ready to be assembled, eliminating the need for further manipulation in the field. Urbem’s factory has Technical Specification Documents, with Volume 04 specifically focusing on machining, explaining exactly what is considered machining, what tools the factory has, and the level of complexity for each cut.

-

- Pay attention to the choice of connections used in the project:

- These are the materials that will join or protect the pieces. There are numerous options for both CLT (Cross Laminated Timber) and GLULAM (Glued Laminated Timber), so it’s essential to evaluate and consider what’s best for each project and its objectives.

These considerations are important because of the relative novelty of this technology in the market, especially since the construction industry is more accustomed to traditional methods. By taking these aspects into account, you ensure greater durability and strength in your mass timber construction.

While it may seem like a lot to consider, some companies offer consulting services when contracted. Urbem, a mass timber industry, for instance, has a team of specialized engineers that assist in adapting projects to wood. It’s always possible to check if the industry or developer you are working with offers similar guidance for your future project.

What are the benefits of choosing mass timber?

- Faster construction, as it is a prefabricated material;

- Reduced debris and waste on-site;

- Safer construction sites;

- Less labor required;

- Stabilization of IRR (Internal Rate of Return);

- Reduced carbon emissions, as wood is the only material that stores carbon instead of emitting it;

- Building with one of the few renewable materials in the construction industry;

- Having a sustainable project that is good for the environment.

Is engineered always wood a sustainable material?

To ensure this, it’s important to verify that the company providing your mass timber is committed to the environment, does not exploit workers, or use wood from deforestation in its production—in other words, that it meets all ESG criteria. This can be confirmed through the FSC® Chain of Custody certification, which guarantees that the organization manages its resources in an environmentally appropriate, socially beneficial, and economically viable way.

By working with a company that holds this certification, you can be confident that your project meets ESG standards and is truly sustainable.